|

||||||||||||||

7812 Erlestoke Manor OverhaulA few images following the overhaul work on 7812 Erlestoke Manor. There's further information on the Erlestoke Manor website. |

||

| May 2008 | ||

|

7812 in Bridgnorth MPD after a successful brake test. This followed a good deal of troubleshooting including dropping both loco and tender vacuum cylinders and machining out some mysterious pitting from the loco cylinder. Erlestoke has since put in some fine performances along the valley! Photographed 17th May: Paul Bennett. |

|

| February 2008 | ||

|

With a feather of steam from the snifter valves, 7812 is back in the shed having clocked-up a 100 miles of trials between BH and HL. |

Mick5eye's YouTube video caught 7812's first moves under its own steam for 22 years. Photographed 23th February, Paul Bennett. |

|

| January 2008 | ||

|

With painting complete 7812 is now in the main shed and coupled up to its tender. Photographed 19th January, Paul Bennett |

The jockey valve is the latest fitting to be added. Just the regulator handle, gauges and drivers side injector to go! |

|

| November 2007 | ||

The paintwork is all but complete, whist some of the smaller pipe runs on the footplate are being finished off. Photographed 17th November, Paul Bennett |

|

|

| October 2007 | ||

Further progress in the paintshop. |

Photographed 13th October, Paul Bennett |

|

September 2007 |

||

With superheater elements in, smokebox pipe work fitted and the chimney on, Elrestoke is now in the paintshop for the final coats of paint and varnish. 22nd September 2007.

|

||

| August 2007 | ||

|

View along the driver's side of 7812... ...the lefthand outside steam pipe ready for fitting along with the other smokebox pipe work and superheater elements... |

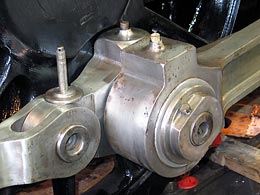

...further work on the front bogie in preparation for the AWS shoe to be fitted... ... much of the cab fitting and pipework installed. 25th August 2007. |

|

| July 2007 | ||

|

Much visible progress over the last couple months and looking almost complete but still with all the smokebox pipe work to complete before the chimney goes on... |

...while EMF volunteers work on the cab fittings and pipework. 27th July 2007. |

|

| May 2007 | ||

|

Following the steam tests the boiler is now back in the boilershop. New lubricator pipework is being installed running along the side of the boiler from the backhead to the smokebox. |

With the bogie wheels turned on the wheel lathe, the bogie is being prepared for reassembly. |

|

| April 2007-2 | ||

|

The retyred bogie wheels have arrived and John sets to with the paint brush... ...while the bogie frames receive similar treatment.

|

Following the steam tests the boiler has been grit blasted and painted in 'go faster' silver. A shot of the cab end of 7812's frames resting on the lifting jacks. |

|

| April 2007-1 | ||

| Work is picking up again on 7812 with the frames back on the lifting jacks while the bogie (ex 7802) is prepared for re-wheeling, which is ready to be reassembled as soon as the retyred wheelsets are delivered.

|

The boiler undergoes a steam test behind the boilershop... ...later in the day with a bit of pressure on the clock. |

|

| August 2006 | ||

|

7802 Bradley Manor running with Erlestoke Manor's new 3500 gallon tender while its own has the wheelsets fitted, bearings re-metalled and, if time permits, an overdue repaint. |

The new wheelsets at Bridgnorth earlier in the year awaiting 7802's 4000 gallon tender to be brought on to the lifting jacks. |

|

| April 2006 | ||

|

Boiler tubes and superheater flues are in and expanded. Only the internal feed water trays await fitting before the hydraulic and steam tests. This boiler was paired with 7802 Bradley Manor until swapped over a few year ago. The front bogie now re-assembled and re-wheeled. Taw Valley's frames are behind with the left-hand cylinder removed. John Whitcomb paints the town red, beginning with the brake cylinder! Three spare tender wheelsets have been prepared to replace Bradley Manor's as the tyres are now rather thin. The third pair is on the wheel lathe, below.

|

On the lifting jacks with the frames now re-wheeled. This sequence of photos shows the re-fitting of the right-hand side connecting rod. The big end bolted up. The knuckle joint bolt is resting on the coupling rod. And the little end connected up to the crosshead.

|

|

September 2005 |

||

|

The tender looks immaculate in its freshly applied livery. This may run behind Bradley Manor for a spell.

|

The later style British Railway logo. |

|

|

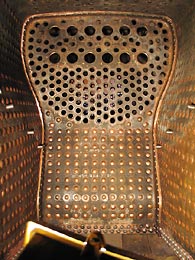

Work on the boiler has progressed very well in Bridgnorth Boilershop and now only awaits retubing before the hydraulic and steam tests. This view is through the firehole into the completed firebox - a work of art!

|

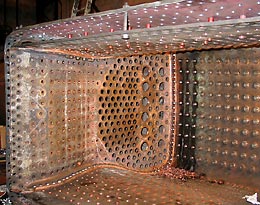

The outer firebox showing the new shoulder plates and the replacement section of the outer wrapper... |

|

|

...and re-furbished smokebox tubeplate at this end.

|

The retyred and and machined wheels await, along with 4566's, to go back under the frames.

|

|

| April 2005 | ||

|

Refurbished piston valves ready to be installed back in the engine.

|

|

The inner copper firebox with side and crown stays being replaced. Two new patches have been formed and riveted to the back shoulders of the outer firebox. If only boiler washouts were this easy! View between the inner (copper) and outer (steel) firebox plates with some of the new copper stays installed. The top plate is new - the lower section of the outer steel wrapper having been replaced.

|

| April 2004 | ||

|

Effectively a brand new tender with new tank and frames, only the wheels, axleboxes and fittings have been reused. The stripped down main frames inside Bridgnorth works. Working on the horn guides. |

Good to see the water scoop has been kept. The boiler is prepared for patches to be applied over the shoulders of the outer firebox. The frames resting on temporary wheels while its own are away for re-tyring. |

|

| |

| Page created June 2005, last updated: 2 June, 2008 Webmaster |