|

||||||||||||||

Musings from Bridgnorth pattern-shopOccasional notes from Brian Oldford beavering away at Bridgnorth's volunteer Pattern-Shop. |

||

| December 2007 - 2 | ||

|

Some years ago we made a pattern for the shut-off valve feeding GW radiators that mounts below the vehicle floor. This was fetched out of store recently as a sample to make an opposite handed version. Whilst studying it, it was decided it would be easier to cast using and odd-side and easier to machine if a chucking stub was added. These two new patterns were made. Photos: Gordon Woodruff |

Meanwhile Gordon is in the process of completing more parts for GW carriage locks in the form of the lock body shewn. Photos: Gordon Woodruff We were recently approached to assist the Sittingbourne and Kemsley Railway with some patterns for the bodies of some cylinder drain cocks. Left hand and right hand variants were asked for and the above photos show the product of out labours. Each consisting of a simple pattern with loose piece inserted into an odd-side. Photos: Brian Oldford

|

|

| December 2007 - 1 | ||

Here is the patterns for parts recently cast for water shut-off valves for tender filter boxes for 43106. |

||

|

This is a good illustration of the contraction allowances we have to build into our pattern making. A test cast of the horn tie for 43106 resulted in a casting no less than 15/16" shorter than the pattern. This minor miscalculation of the contraction of steel resulted in the first horn tie having barely enough machining allowance on the inner faces. Two more horn ties from 43106 were found to be required as more were found to be cracked. Before the pattern was sent to the foundry again it was modified so the additional 2 required for 43106 will be spot-on. No doubt the 82045 team will be pleased to know yet another proven pattern now exists. Photos: Paul Bennett |

||

| November 2007 | ||

|

Whilst on its travels, 813 is to masquerade as long lost classmates. 816 being one example. Cast in iron from a pattern made by one Niell Parker. Photos: by Des Ainsworth |

Gordon has recently been completing some parts for GW carriage door locks. This component (when machined) is the part that is rotated with a carriage key when the door is locked off. |

|

| September 2007 | ||

|

As Paul (our webmaster) will attest, the 2857 team have been working extremely hard with the boiler repair. The team also thought it fitting to grace the tender with a tender plate showing the correct number and water capacity. Here we have the product of a joint effort by Niell Parker and myself. For those readers wanting to know the modus operandi we used read on... To make a plug for GRP moulding I mounted the plate on wax sheet covered plywood and filled the bolt holes with plasticine. I then coated the whole with Poly-Vinyl Alcohol (PVA) mould release compound. (Wikipeadia PVA entry.) The next step was to coat it with Gel-coat followed by three coats of Chopped Glass Mat layed up with Polyester Resin. Although most resins will appear to cure within hours they continue to cure (and thus possibly distort) for a number of days afterwards. As a volunteer who is a wage-slave this was left until the following weekend before it was parted from the plug. I rinsed the PVA residue from the embryo mould with plain water and dried it thoroughly. As a negative copy of a tender plate, what were raised letters and numbers were now depressions. The depression of the unwanted numbers (tender number and capacity) were then slightly over-filled with more Gel-coat and set aside to cure. When the gel-coat was completely cured it was rubbed back to the surface level of the original plate with a series of graded abrasive papers finishing with well worn wetted 1200 grade carborundum paper. This prepared mould was coated with PVA and when dry a GRP replica of the original cast iron plate was made (minus the unwanted tender number and capacity) repeating much of the previously noted procedure. When parted the raw rear GRP was overcoated to produce a smooth surface and the rib detail was added. Far easier said than done, this was then passed to fret-saw expert Neill Parker who, again, painstakingly manufactured numbers in the appropriate font. These were then glued onto the GRP plate and the whole painted ready for despatch to the foundry. Why go to all this bother, you might ask? The rationale is, in future, we can easily remove the newly applied numbers if/when another tender plate is needed. No two were alike. |

Clearly I'm suffering from a middle-aged moment! All I can say about the above are they a couple of replica makers plates made by Niell Parker for another railway whose name escapes me. For many of the letters Niell was unable to use standard pattern makers pressed brass or cast white metal letters as the correct font wasn't available. Ever resourceful he painstakingly made many of them by cutting them individually on the fret-saw. Yet another illustration of how we try very hard to get things right.

|

|

| September 2007 | ||

Despite the silly season when everyone seems to be sloping off on holiday we've managed to complete a few jobs.

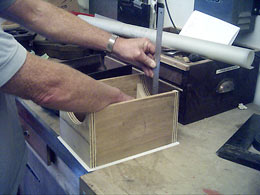

Evidence of Neill Parker's industriousness. Most of our LNER carriages have been modified to use BR Std brake blocks. We're informed such a modification isn't a practical proposition for the buffet cars because of their weight. Not wishing to be caught out with a shortage of spares Hugh McQuade requested the manufacture of a pattern for said stopping stuff. Gordon seen to be busy making the patterns for replacement Pony Truck Axle Box Keeps for 43106. The original steel keeps are in very poor condition and policy nowadays is to fit bronze keeps whenever possible. Steel keeps can cause damage to axle journals if the weight of the wheel-set is taken by the keep since a steel bearing on steel condition occurs. Dis-similar materials make for a far better combination. We were recently approached to assist the in the manufacture of North Staffs style platform bench frames for eventual use on the Churnet Valley. The photograph, right, shows one half of the double sided boxed pattern. A pattern as simple as this would often be unboxed, relying on the foundry to use their flasks. I considered this pattern to be a little too thin and flexible for this approach and it was thus boxed.

|

Again, another pattern created by Gordon. This time for our friendly boilersmiths. As may be appreciated quite a few of the boilersmiths' tools are quite specialised. One particular item associated with the task of rivetting dates from WWII and hence spare parts are thin on the ground. Our Mr Beddow has worked some of these tools to death and replacements are needed. Three guesses whose shoulder was tapped? A simple end cover for one of his pneumatic machines complete with odd-side. These two photos, above, show the major corebox and one of the three smaller corebox for the 10mm Davis & Metcalf Monitor Injector body. The smaller corebox produces a 'banjo' type core to fit around the portion of the main core that creates the delivery outlet. This pattern follows the same scheme as I used for its 8mm smaller brother. Incidentally, no drawings existed for the 8mm injector so Charles Lamont spent many hours preparing a set of drawings from an existing casting. |

|

| June 2007 | ||

|

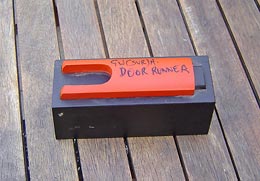

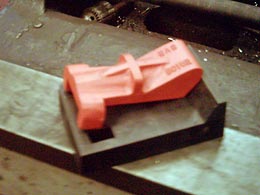

Above is an original double signal pulley wire wheel bracket casting supplied to me by John Smith of the S&T. Here are one side of the boarded patterns to cast the single, double, treble and quad variants. The rear of the boards carries the other half the patterns. A regular split pattern would have been quite fragile. I think the pulley wheel will be coming my way before long. Neill Parker managed to be persuaded to take enough time away from the footplate to complete this GWR door runner pattern for Colin Jenkins. An original can be seen on 9103 Saloon.

|

When 43106 was de-wheeled after being put onto the jacks one of the horn stays was found to be broken.

To ensure no delay can be attributed to the pattern shop I produced the above pattern and odd-side over a couple of weekends.

|

|

| May 2007 | ||

Just a couple shots of work recently completed this time. The first is a pattern for a solebar plate to be attached to vehicles owned by the SVR Rolling Stock Trust. Presumably to assist a finder return them to their rightful owner should they become mislaid! The second is a collection of 5 small patterns on an oddside for parts for the emergency braking mechanism for the Barry coach. It is thought these are probably to an early GWR design as various fittings were Westernised of absorbed vehicles. |

It occurs that others may wish to contribute showing what other "back room boys" are doing, illustrating the quality and authenticity our restorations. There's so much more going on behind the scenes; creating that glorious glow on the teak carriages, machining raw casting up to finished items ready for installation and the seemingly satanic art of boilersmithing to name a few and I'm sure there are many other volunteer and paid staff activities that could be included. I'd be interested for others to contribute via the webmaster, who will do the rest! |

|

| March 2007 | ||

| A few of the test castings for the point rodding roller brackets arrived during the week. Before being passed to Adrian Hassell of the S&T dept, Gordon Woodruff managed to grab a couple of pictures. Although many of the parts we have a hand in producing are not overly exciting, without them we cannot operate our railway.

|

||

Contrary to popular belief the pattern shop is still very active. Of late much work has taken place although little progress can be seen. One major job is the ongoing 10mm Monitor injector. The major corebox is complete but the project has had to be sidelined whilst other, more pressing, items are dealt with. This is the pattern set for part of the drawgear for a GWR wagon recently completed by Niell Parker. Despite rumours, he can be persuaded away from the footplate to finish projects. The is presently awaiting dispatch to Barr & Grosvenor when our C&W friends at Bewdley determine how many are required. Some months ago Niell was asked to produce a pattern for loco coal picks. These are to be cast in steel. A test cast have revealed far greater contraction than expected so Niell is having to enlarge the corebox and core print to accommodate the metal clad shafts that have be sourced by Bob Heath. This is a casting produced from the pattern for the GW smokebox lubricator splitter. They soon loose the shine in their hostile working environment. This is the pattern and corebox for the lower section of a combining cone within a GWR 10X injector. The core is to produce the gap between the end of the combining cone and the delivery cone. This is the pattern for the upper section of the combining cone. When machined this is attached to the lower portion by a hinged joint. I understand this assists the GW style horizontal injectors to 'pick-up'. I'm informed that the reason such moving parts are unnecessary on Monitor injectors is because they operate vertically. I'll allow another to produce a treatise on the finer workings of injectors! |

This is the pattern and corebox for the lower section of the combining cone within a GWR 8X injector. Although this pattern was made on behalf of and owned by the Pontypool and Blaenavon it is stored in the SVR's pattern loft. I was requested, for our mutual benefit, to modify it to accept a core to produce the combining cone/delivery cone gap. Incorrectly attributed to me in the latest SVR News, Gordon Woodruff has completed a reduced diameter dynamo pulley. This is to allow the dynamo to think the train is traveling at greater than 25mph and thus charge the coach batteries better. This scheme will be used on those coaches that cannot be modified to the system designed by a K&WVR member. This system is only suitable for a particular type of voltage regulator. The cores at each end are identical and thus only one corebox is required being made twice. Along with a whole raft of internal door handle parts for our GWR carriages, Colin Jenkins brought along a rather nice drawing from Phil James for the lamps for LNER Kitchen Composite 7960. Contrary to earlier reports these will be wall mounted adding to the elegance of this vehicle. Phil has been very kind to me and agreed to use the lampholder casting made for the table lamps for LMS RFO 7511. Colin also managed to find me some more work for his own projects in the form of a rather worn part off GW corridor connections.

|

|

January 2007 |

||

Some coach parts have been cast from some of the recently made patterns. Here's the door stop spring loaded plug, the corridor hand rail end and the water pipe nut. |

Here we have the castings for the mixer valve, both the main body and the push valve and the door stop receiver. |

|

| January 2007 | ||

Not too much progress over the last couple of weeks whilst the waistline and the malt has taken a hammering but we've managed to come up with some work! A few GW sandbox lids have now been cast. Here’s the results of Gordon's efforts. I've recently completed a pattern for a GW lubricator splitter that I believe fits inside the smokebox. |

And a quick visit to the 7511 guys at Bridgnorth. They have received the first tranche of lamp castings back from the foundry. We spent a bit of time weighing up the next stages, i.e. fitting on/off switch, electrical connector, tubular stem and secure window ledge fitting method.

|

|

| |

| © 2006 GW(SVR) Association. Page created May 2006, last updated: 9 September, 2008 Webmaster |