|

||||||||||||||

Musings from Bridgnorth Pattern-shop - 2009Occasional notes from the team beavering away at Bridgnorth's Pattern-Shop. |

||

| September 2009 | ||

|

The result of many hours of work at the Bridgnorth Pattern Shop - patterns and numerous core boxes for 82045. These include; centre hornblock, horn guides and the firebox support bracket. The split screen Moggie gives some scale to these substantial pieces of work. Regular readers may recall we completed the patterns for the S&T signal wire pulley frames in 2007. John Smith of the S&T department has sent a photo of a recently cast, and subsequently machined, pulley wheel frame. Fitted with original pulleys it demonstrates how we try to make new parts as compatible as possible with originals. Meanwhile somewhere in darkest Shrewsbury (Gordon's garage) work continues to complete a pattern set for the pulleys themselves. And now installed! The new pulley shows the off-set split pin allowing a grease nipple to be fitted to ease future maintenance. A batch of newly cast pulleys (to Gordon Woodruff's pattern) have recently been delivered to Bridgnorth. They will need to be drilled before installation. A batch of recently cast small GW style firehole doors. These are the same type used on the BR Std 3's although 82045 has a pair already. The hinge patterns and oddside for the Barry Coach at Hampton Loade. The patterns were made by making an RTV mould from original parts having doctored them with sheet wax and plasticine. The RTV being cast into a plywood moulding box. After the RTV had set polyester resin was cast into the RTV moulds, minor blemishes filled and fettled before the oddside was made to carry both hinge parts. Paul Vidler has made an excellent job in cataloguing all the Loco patterns. The complete list is online on the pattern making page of the new SVR-Engineering site. SVR patternmaker Brian Oldford has now set up his own company and invites enquiries from interested parties. Brian has many years of experience of making a comprehensive range of patterns for groups on and around the Railway. Two fine examples of his work are the roof crestings for Kidderminster Town Station and the driving wheel pattern for new build Riddles tank 82045 - this is on temporary display at The Engine House pending casting. He has also produced a number of top-quality patterns for The 82045 Locomotive Fund, including the firebox support bracket frame stretcher, buffer beam gussets, horn guides and complex horn block. Brian offers a highly skilled service at a realistic cost. Ask him to quote you for your patterns! brian.oldford@yahoo.co.uk

|

Here's the scroll that is attached to the rear of the half-harp on the new gas lamps at Brigdnorth Station. This pattern for the cast representation of wrought iron was made by fret sawing from a piece of Sikablock sourced from our friends at John Burn, Stetchford. The completed pattern for the adaptor between the half harps and the top of the lamp posts. The method used to produce the floral detail has been featured earlier. This was subsequently attached to the lower portion of the pattern and core print turned from Jelutong. Being a one piece pattern it was necessary to create an odd-side shown underneath the pattern. The hollow underside was produced with a parallel cylindrical corebox. Three adaptors cast from the pattern above following machining and painting. A collection of half harps awaiting final paint. These three photos show the attachment detail betwixt the half harps and the lanterns supplied by the good people at Steelway along at various stages of assembly. The completed lamps mounted on the post... ...and now doing the job they're intended for! |

|

| May 2009 | ||

The SVR recently took delivery of the 2857 patterns which until recently had been managed by the group independently. The 2857 group had decided to donate them as it was felt their use would be better managed via formal SVR channels. Whilst this centralises things from prospective customers' view points, the down-side is our pattern storage problems are exacerbated! Paul Vidler will merge them into the SVR's Pattern Catalogue in due course. The patterns include:

Over the last few months Paul has been auditing the patterns and reviewing the catalogue for errors and omissions. In those few instances where pattern parts have been lost or damaged we are carrying out the necessary repairs/replacements in between other mainstream jobs. |

Visitors to Bridgnorth may have noticed the erection of new cast iron lighting columns on platform 1. Although the half-harps and lantern/luminaires are all to hand progress on this stalled because of the shortage of adaptors to fit between the top of the column and the base of the half-harps. Although not of GW origin a design has, at last, been developed that includes sufficient original features to satisfy all but the most ardent purist. The decorative feature of these adaptors has been replicated in the pattern by moulding in RTV (Room Temperature Vulcanising) Silicon from the corresponding feature on one of the footbridge lamps and then subsequently making a polyester resin casting into the mould produced. It is now down to yours truly to complete the pattern set before passing it to Chris Thomas to arrange further stages of the project. Users of the bridge will be pleased to know the lamp has now been returned to its rightful place. No, not a new fireplace for the booking office! The construction for the substantial center hornblock pattern for 82045 continues.

|

|

| April 2009 | ||

Another busy month in the Pattern Shop. Many hours have been invested to bring the horn guide pattern for 82045 through to completion. The picture above shows the two horn guides and associated core boxes. This picture shows the way the various loose pieces fit onto one of the axlebox guide patterns. To permit release from the moulding sand each of these is constructed with a number of loose-pieces and cores. It may be of interest to note that the design of these axlebox guides is derived from those fitted to 43106. The adaptation between the LMS oil lubrication and BR grease lubrication is so slight that castings made from these patterns could be used on the Ivatt Class 4 and the closely related BR Standards Class 3's (82xxx & 77xxx) and Class 4's (80xxx, 75xxx and 76xxx) if machined appropriately.

|

A recent delivery of smokebox number plate, oil boxes, steam heat adaptors and retaining valves. This picture shows the very beginnings of the massive center hornblock pattern for 82045. Yet another big 'un in our small shop! |

|

| March 2009 | ||

The first update from Bridgnorth pattern shop for 2009 but we've not been idle! The driving wheel pattern for 82045 is finally complete and now on its way to the Engine House at Highley where it will go on public display.

|

|

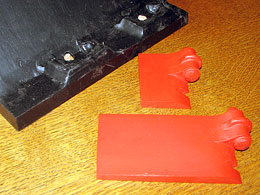

This is the pattern and core boxes for the Firebox Support Bracket for 82045. This also forms a substantial stretcher and hence is needed fairly early in the locomotive's construction. I elected to run the 'split-line' of the pattern vertically to reduce the number of coreboxes needed and the number of cores needed to be made by the moulder at the foundry. This will be cast in the same grade of steel to that of the buffer beam brackets and horn ties.

Recently we have also completed the minor coreboxes for one of the GW combined ejector blower rings and a small external job which will lead to Henwick Signal Box once again being adorned with a GW style nameplate. |

| |

| © 2009 GW(SVR) Association. Page created March 2009, last updated: 30 September, 2009 Webmaster |