|

||||||||||||||

2242 Hawksworth Brake Third - RestorationA few images and notes of the work on 2242 Hawksworth Brake Third prior to entering traffic on the railway.

|

||

| December 2020 | ||

We're back at work! The new floor is fitted and screwed down in the compartment no 4. The repairs to the corridor body brackets are progressing with Michael Catton cutting out of the rotten parts of the bottom side.

|

The Guard's Van with new floor and inspection flap. The guard’s area has been re-scumbled and prepared for refixing. |

|

| May 2020 | ||

|

||

| April 2020 | ||

|

2242 being shunted into Kidderminster works. 8th April. Photo: Alan Brookes.

|

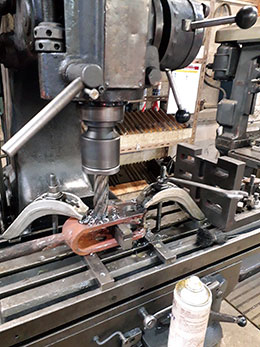

2242 wheel set swop in progress. Photo: Nigel Hanson. |

|

| Hawksworth Brake Third 2242 Appeal | ||

We are renewing our appeal for funds in these challenging times. The GW(SVR)A have agreed to bring forward the mechanical work on Hawksworth Brake Third 2242 under contract which will help the SVR to meet some of the costs of the full time carriage staff over the next few weeks. Read more… |

||

| |

|

|