|

||||||||||||||

2426 Churchward Toplight Third - RestorationThe 1910 built toplight third 2426 is now resident at Bewdley. The roof has been covered and broken windows replaced. It is being converted to act as a workshop for 5043 and a varnish shop for us. It needs substantial structural repair and we have made a start on the north end. Parts are being made such as door locks and commode handles. It is mounted on 8 foot American bogies and drawings are slowly being found to aid restoration which is following on from 4786. 2426 Churchward Third Restoration Appeal - how to help return the Railway's oldest coach into service.

|

||

| February 2026 | ||

|

A trial fit of a compartment door on its top runner with the bearer for the corridor ceiling above the pole blocks. The trial was very successful and included the strike post and the brass guide at the base. More sections will now be fitted. The pattress fitted on the underside for the roof below the ventilator to carry the drip tray. There are 18 of these on a toplight.

|

Some of the other ongoing work includes: The vestibule light frames have received their reflectors and been attached to their bases. These are now being painted. The 14th seat back has been fitted with the 12 springs and only needs stringing and sanding. The corridor partition between 5 and 6 has been installed as partition between 6 & 7 is now complete apart from sanding and priming. Work now can begin on the last partition, the one between 7 & 8. The fabrication of the corridor roof hoops has reached 8 out of 13 in total. The first of the compartment ceiling frames was tried in one of the compartments and fits well. The second one is now made up and once 2 are ready we can check out a complete frame in one compartment! Staining and varnishing of the toplight oak moulding frames is progressing although they are slow to dry in this weather. All the door brass runners in the corridor have been drilled and countersunk ready to be installed. The vestibule doors both have a tapered packing section under them to help the door to keep closed when on the move. These have been made and are being coated in Danish oil for protection as the sit above the floor and are subject to damp. The light switch pattresses have been drilled and primed. The first set of blinds have gone off to the upholsterer for fitting to the carcases.

|

|

|

The jig for assembling the corridor ceiling hoops, along with one for the compartment ceiling frames, is being put to good use and 6 have been made so far - 7 more to go. Photo: Mick Haynes. The corridor ceiling frames in progress, also the light switch pattresses. Photo: Mick Haynes. The pads to go under the ceiling ventilators are now in finishing and these will need to be fitted before the trays can be attached.

|

Some of the other ongoing work includes: The north-end lavatory ceiling panels were taken down, cleaned up and dried out and are now painted with primer and undercoat. The south-end lavatory has had its window fitted and work has begun on fitting the hopper. The design is slightly different to a bow ender so some research and thinking is needed! Ralph has been fettling two comms boxes and they are mainly OK but improvements to the fitting of the lids is necessary - brass is on order to solve this. All the work on the vestibule lamps is complete and so they can have their reflectors fitted and be reassembled. Good progress has been made with the bearers that go above the sliding doors and support the ceiling edges and the corridor architrave. These have been shaped and drilled for fitting. The two sections that run above the end sliding doors have been made, drilled and countersunk. Seat back 12A is complete and 14 has the full frame is assembled. The partition between 6 & 7 is now complete, apart from the final screwing together of the T&G. More progress has been achieved on the compartment side frame with preparation of the bottom side repairs between compartments 1 & 2.

|

|

| January 2026 | ||

|

Painting is taking place on the wooden pattresses to be fitted under the ceiling holes for the roof ventilators. The "ashes'" trays will then be added to catch any ash and water ingress from each ventilator. Photo: Robin Organ. The framework for the false ceiling in the Lav at the south-end has been fitted. Work has begun to install the window and hopper. Photos: Rob Massey.

|

The vestibule ceiling frame at the north-end now with light support above entrance to the lav. Photo: Rob Massey. Some of the other ongoing work includes: Seat back 12a is complete except for sanding, leaving just 3 more to do. The corridor partition between 6 & 7 has been glued together and the channel routed out to take the central post to fix it to the ceiling. The top bearer to go along the partition above the sliding doors is being machined. This will support the ceiling hoops and the ceiling plywood. The top bearers to go above the vestibule sliding doors has been machined. Further staining and varnishing of the quarterlight beads is proceeding well. Paul has been making and refitting 3/8" T & G to replace warped panelling in the lavatory. Two new communications boxes have been cleaned up by Ralph. We need one for 2426 and one for the "Dimbo" valve for 2242.

|

|

|

The north end vestibule ceiling is mainly in place. Photos: Rob Massey.

|

Some of the other ongoing work includes: A kit of sections for the ceiling frame in the lavatory at the south-end has been prepared, thanks to Jim Scaife, who joined us on Tuesday and Wednesday. Jim has installed the vertical section above the cantrail. All 32 armrests have now been stained and varnished. Dave is staining and varnishing the first of the quarterlight retaining beads for the glass. The smaller steel bar fits above the sliding door so the next job is to machine the new rollers to fit the bar. The sliding doors sit behind a pelmet, which is screwed onto a 2 1/2" x 1 1/4" bearer running down the whole length of the corridor. This is now being made. It supports both the corridor ceiling hoops and the side of the plywood corridor ceiling. Seat back 12A is now almost ready to receive its springs. The corridor partition between compartments 6 & 7 now just needs the rebate for post and the lower sections of T&G. Michael Bradley has delivered the reflectors for the vestibule lights and these will now receive gloss white from Robin. Parts for the north end communication apparatus are being assembled/made.

|

|

|

The first corridor compartment sliding door is being trial installed and is showing a few issues to be resolved. An example is the door strike posts which will need thinning a little to correctly accommodate its moulding. Photo: Mick Haynes. The framework for the vestibule ceiling at the north end is beginning to be installed. Photos: Rob Massey.

|

All armrests are being stained and varnished. Photos: Robin Organ. Some of the other ongoing work includes: Seatback 12 is complete and 12a frame is partially assembled. (12a = 13 for the superstitious!) The jig for the corridor hoops to support the ceiling now has its first hoop made of 5 laminations. The corridor partition between 6 & 7 is assembled sufficiently for the lower T&G to be fitted.

|

|

|

The corridor partition quarterlights have been receiving their glazing strips. They have been mitred at the top and have corner blocks at the bottom. They will be screwed in once the 6mm glass (or ply) is made. Photo: Mick Haynes.

|

The false ceiling in the south end vestibule. The bearer for the ceiling light is in place and the rest are now screwed in place. The complex corner support for the ceilings is being developed by Brian. Photo: Mick Haynes. Some of the other ongoing work includes: All 32 arm rests are now assembled with their brackets. Next will be to varnish the undersides and to make a template to fit them. Seat back 12 is now ready for its springs. Corridor partition between 6 & 7 is partially assembled with the upper T&G fitted. Work has begun on the north end with refitting of the vertical T&G and cutting of the 2x2 softwood sections.

|

|

| December 2025 | ||

|

Rob, John Bendall and Mick have made good progress with the vestibule ceiling framework. The longitudinal(s) are jointed in both ends, but the transverse ones are still to do. The photos show those in their approximate positions. Photo: Rob Massey.

|

Dave has been installing the toplight glazing beads and most are now in place. Photo: Rob Massey. Oak framing for the external topights. Photo: Rob Massey. Robin is refreshing some lamp reflectors and leather grab handle covers along with some ceiling ventilators and the arm rest brackets. Photo: Robin Organ.

|

|

|

The new partition wall between 6 and 7. Photo: Rob Massey. Robin has been painting the ventilators and some spare light reflectors. Photo: Robin Organ.

|

Some of the other ongoing work includes:

|

|

|

The artificial corridor wall to the first bedroom in the Camping Coach has been removed. Here, Rob is shaping the initial section of vertical T&G, which butts against the external wall to form the compartment wall between 6 & 7. Photo: Mick Haynes. The fitting of the brackets to the new armrests is progressing; here Robin is painting them in his cubby hole or "Caerphilly Works" as he calls it! Photo: Robin Organ.

|

Some of the other ongoing work includes:

|

|

| November 2025 | ||

|

The Regulator Cupboard is now back in the carriage, ready for the installation of the electrics to start. Photos: Rob Massey. The light and dark oak scumbling of the cupboard doors. Photos: Mick Haynes.

|

Compartment 6 is now ready for reinstating the wall between 6 and 7. Photo: Rob Massey. Looking towards compartment 7. Photo: Rob Massey. Some of the other ongoing work includes:

|

|

|

A welcome return visit from Alec and Jasmine, who removed the partition delineating the first bedroom when it was a Camp Coach. This permits us to begin to install the compartment partition between compartments 6 and 7. Photo: Dave Smith. Trial section of oak scumbling by Dave. Photo: Mick Haynes.

|

Ralph using the new router to fit brackets to an armrest. Here he's making blocks to go below the window bottom rail in each compartment to allow the new armrests to be screwed into place. Each armrest requires 2 metal brackets to be screwed into the wall below the waist rail. Photo: Dave Smith. Some of the other ongoing work includes:

|

|

|

The 4th corridor partition installed. Photo: Mick Haynes.

|

The new remade end-panel, fitted after door post repair. Photo: Rob Massey. Some of the other ongoing work includes:

|

|

|

Oak being machined for the 4 door post repairs. Photo: Mick Haynes. Some of the other ongoing work includes:

|

Painting is continuing on the vestibules and has begun on the regulator cupboard. Photo: Mick Haynes.

|

|

| October 2025 | ||

|

Door 6 removed for attention to bottomside. Photo: Mick Haynes. The south-end vestibule being painted. Photo: Mick Haynes.

|

The compartment wall 5-6 being installed: Photo: Mick Haynes.

|

|

|

The Regulator Cupboard fitted. Photo: Dave Smith. Bottomside repairs progressing. Photo: Mick Haynes.

|

The compartment wall between compartments 4 and 5 being stripped. Photo: Mick Haynes.

|

|

| September 2025 | ||

|

The compartment side bottom-side repairs progressing with new oak. New oak has now been machined for 7 out of the 8 compartments. Photo: Mick Haynes.

|

New oak for the door thresholds. Photo: Mick Haynes.

|

|

|

The corridor external wall being cleaned and primed. Photo: Mick Haynes. The corridor T&G - looking good! Photo: Mick Haynes.

|

The lavatory partition being installed. Photo: Mick Haynes. |

|

|

Panels drilled and punched. Photo: Rob Massey. Welcome back Ralph who is coating the T&G in Danish Oil. Photo: Dave Smith.

|

Trial fitting of the upper panels. Photo: Rob Massey. |

|

|

The steam heat rods fitted in the first compartment. Photo: Dave Smith. Further prep work for the bottom side repairs. Photo: Dave Smith. |

A close up of the heater rack. Photo: Dave Smith. Mike and Dave assembling the next seat back. Photo: Dave Smith. |

|

| August 2025 | ||

|

Corridor bollection fitted to the corridor-side: Photo: Rob Massey. The bottom side along the compartment-side being cut back for repair. Photo: Mick Haynes.

|

The south-end vestibule sliding door completed. Photo: Rob Massey. The panels have been drilled and punched, painted on the back and fitted into place. Photo: Rob Massey. |

|

| July 2025 | ||

|

The south-end town-side, new panels have been cut out and offered up for fitting. Photo: Rob Massey.

|

|

|

|

The north-end vestibule door varnished. Photo: Rob Massey. The compartment-side end section almost ready for panelling. Photo: Rob Massey. |

The north-end vestibule door, external side. Photo: Rob Massey. The new oval buffers have been delivered. Photo: Rob Massey. Flying Scotsman at Bewdley preparing for the re-opening train. Photo: Dave Smith.

|

|

|

The new buffers finished, and ready for delivery and a trial fit. Photo: Somers Forge. The third seat back is assembled and is ready for stringing the springs. This is a heater style and will be fitted in compartment 1 to help set up the heater rodding. Photo: Dave Smith.

|

A section of the compartment-side frame work being prepared for repairs. Photo: Mick Haynes. An archive photo of the eating area when 2426 was converted to a Camp Coach at Swindon in 1952.

|

|

|

Looking north along the reinstated corridor, the compartment wall between compartments 3 and 4 has been completed and the corridor partition installed. Photo: Dave Smith.

|

Looking south along corridor, doorway headers set in place. Photo: Dave Smith. |

|

|

Sprung seat base and seat back in the compartment. Photo: Dave Smith.

|

Seat back springs now strung.

|

|

| June 2025 | ||

|

Springs are now being installed on the first 2 backs. They now require stringing to hold in place at the correct depth. All 12 springs in place. Photo: Dave Smith.

|

A close up of new springs. Photo: Dave Smith. |

|

|

The partition between compartments 2 & 3 being installed. This will support the roof at its correction height. Photo: Rob Massey.

|

In compartment 1 a seat base, a back and the armrests have been trail fitted to prove all the dimensions are correct and to drawing. Photo: Rob Massey.

|

|

|

Dave and Mike assembling seat back no 1. Photo: Dave Smith.

|

Jim Scaife fixing the support boards for armrests seat bases and commode handles bolts. Photo: Dave Smith. |

|

|

The south-end now with the gangway frame fitted and bedded in. Photo: Dave Smith.

|

The south-end now in black undercoat and ready for the the gangway frame to be fitted. Photo: Rob Massey. |

|

| May 2025 | ||

|

Mick Haynes bandsawing the next seat back-side. Photo: Dave Smith. The first seat back being assembled. Photo: Dave Smith. Further seat back-side members. Photo: Dave Smith.

|

Both partitions now complete. Photo: Dave Smith. Dave Orchard working on seat base no. 15. Photo: Dave Smith. The south-end with all mouldings fitted, filled and primed. Photo: Dave Smith.

|

|

|

The first compartment partition is complete and the inside of the compartment wall has been sanded and filled ready for primer. Work is progressing on the second compartment partition with many of the boards cut ready to fit. Photo: Mick Haynes. Most of the beading at the south end has been installed and the gangway frame temporarily fitted. Photo: Rob Massey.

|

The Association's Collet Third 1086 took a trip to the West Somerset Railway to join the return to traffic of GWR 6705 Collett Brake Corridor Composite. 6705 was repatriated from the USA in 2007 and subsequently restored by the West Somerset Railway Heritage Trust. 1086 waits in the platform at Bishops Lydeard. Photo: Dave Smith. 1086 and 6705 behind the Bluebell's Terrier Fenchurch. Photo: Dave Smith.

|

|

|

The mouldings being fitted to the south-end. Photo: Rob Massey. The completed buffer forging at Somers Forge in Halesowen. Photo: Graham Gardener. 6880 Betton Grange arriving at Bewdley with the Great Western set. Photo: Rob Massey. 6880 leaving Bewdley for Bridgnorth. Photo: Rob Massey. |

One of our founding members, Colin Jenkins, came over from South Africa to help fit the first compartment partition. Photo: Mick Haynes. Working on the repairs to the second partition. Photo: Colin Jenkins. The first corridor partition sections are now fitted permantently. Photo: Colin Jenkins.

|

|

| April 2025 | ||

|

Compartment sliding door no.1 the varnishing started. Photo: Mick Haynes. A large delivery of T&G has arrived which will form the first 4 compartment partitions. Photo: Mick Haynes.

|

Partition no.4 stripped for rebuilding. Photo: Mick Haynes. Forging of the new oval buffers for 2426. This took place at Somers Forge in Halesowen. Here the oven's open with ingot extracted for processing. Photo: Mick Haynes. The ingot in the press with bars used for marking each section. Photo: Mick Haynes. |

|

|

Rob Massey painting the new sheets. Photo: Dave Smith. Compartment No1 door varnished. Photo: Rob Massey. |

Painting of the end complete. Photo: Rob Massey. |

|

| March 2025 | ||

|

Both south-end panels in place. Photo: Dave Smith.

|

Compartment door No 5 receiving stain and varnish. Photo: Dave Smith.

|

|

|

Corridor partition No 3 receiving its T&G. Photo: Mick Haynes. Corridor partition number 2. Photo: Mick Haynes. The second partition being trial fitted. Photo: Mick Haynes. View from inside compartment No 2: Photo: Mick Haynes.

|

The south-end T&G being fitted. Photo: MickHaynes.

Ralph at work. Photo: Dave Smith. The first south-end panel being marked out. Photo: Mick Haynes. |

|

| February 2025 | ||

Two half panels sanded and primed. Photo: Mick Haynes. More seat base progress. Photo: Dave Smith.

|

|

Mike Freeman tightening the seat bolts at Kidderminster stores. Photo: Dave Smith.

|

|

The new and repaired seat base. Photo: Dave Smith.

|

The new seat base assembly complete with steel angles and the spring base trial fitted. Photo: Dave Smith.

|

|

| January 2025 | ||

|

Seat base 8 needs a new frame! Photo: Dave Smith.

|

|

The new seat base no. 8 under construction. Photo: Dave Smith.

|

|

The half partition ready for T&G. Photo: Brian Oldford.

|

The new partition corner post. Photo: Brian Oldford.

|

|

| December 2024 | ||

|

Seat base no. 4 being worked on along with partition no. 3. Photo: Mick Haynes.

|

Work continuing on the haif partitions for end compartments one and eight. Photo:Mick Haynes.

|

|

|

Progress with the partitions and the seat bases. Photo: Mick Haynes.

|

|

|

|

Gusset plates and body brackets installed Photo: Rob Massey.

|

View of floor repairs and corner bracket. Photo: Rob Massey.

|

|

| November 2024 | ||

|

The corridor-side framework glued into place. Photo: Mick Haynes.

|

The second partition approaches completion. Photo: Mick Haynes.

|

|

| October 2024 | ||

|

The new framework on the railway-side has been dry assembled. The two lower horizontal rails need fitting and then after a little routing the section can be glued into place. Photo: Mick Haynes.

|

There's been good progress on the second of the corridor panels. The photo shows it assembled with the central Tongue and Groove. It now needs the lower T&G plus the centre ceiling post. Photo: Mick Haynes.

|

|

|

The corner post dry-fitted. Photo: Brian Oldford.

|

The back rail to lavatory window replaced. Photo: Mick Haynes. |

|

| September 2024 | ||

|

The new corner post partially fitted (on the left-hand side). Photo: Mick Haynes.

|

||

|

Following repairs to the floor joists it has been possible to cut out buffalo board and install to form the bottom layer of flooring. Work is also progressing on the repair to the railway-side door post. Photo: Mick Haynes. The first adjusted seat base is now complete. 15 more to go! Photo: Mick Haynes. |

Part of new corner post at the south-end. Photo: Mick Haynes.

|

|

| August 2024 | ||

|

The new bottom-side section in place, south-end railway side. Photo: Gareth Price.

|

The new bottom-side now fitted, viewed from inside the coach. Photo: Rob Massey.

|

|

|

New oak has been machined for the bottom side and the old has been removed. Here the new section is being being prepared for fitting. Photo: Mick Haynes.

|

Work has now begun modifying the first of 16 seat bases. These require a reduction in depth as the compartments on 2426 are 5 foot 10 ½ inches instead of 6 foot the seats were made for. Photo: Dave Smith.

|

|

|

Decayed corner post removed. Photo: Gareth Price.

|

Templates for a new corner post. Photo: Gareth Price.

|

|

| July 2024 | ||

|

The new south-end, bottom side trial fitted. Photo: Rob Massey. |

The bottom side being prepared for final fitting. Photo: Mick Haynes. The corner post repair now tenoned into the bottom side. These will be bolted into place before the new sections of posts can be fitted. Photo: Mick Haynes.

|

|

| June 2024 | ||

|

Compartment doors nos. 3 and 6 are now varnished. Photo: Mick Haynes. Progress on the south-end frame. Photo: Mick Haynes. The north end with most of the end steps fitted. Photo: Mick Haynes. The north end mouldings completed and now in black - a mix of undercoat and finishing. Photo: Rob Massey.

|

New top, centre and bottom hinges. A new set has been made for all 16 external doors. Photo Live Steam Models. Washbasin fitted. Photo: Mick Haynes.

|

|

| May 2024 | ||

|

Compartment door, the view facing corridor. Photo: Dave Massey. The north-end with mouldings and the toilet door being trial fitted. Photo: Rob Massey. |

Compartment door varnished, inside view. Photo: Dave Massey. |

|

|

The new end-bar laying next to old decayed original. Photo: Rob Massey. The end-bar in place. Photo: Rob Massey. The new end-bar viewed from the interior. Photo: Rob Massey.

|

The first of the compartment doors being varnished. Photo: Mick Haynes. |

|

| April 2024 | ||

|

Further end mouldings fitted. Photo: Rob Massey. The north end painted ready to receive the next mouldings. Photo: Rob Massey.

|

The north end lavatory door, a mix of walnut and mahogany. Photo: Rob Massey.

|

|

|

A compartment door now fitted with blind cover. The partition has been temporarily screwed together to enable it to be trial fitted in 2426 to confirm the exact dimensions. Photos: Mick Haynes |

The end gangway frame now attached. The vestibule door now has its bottom 'V' channel and its plungers. It has been fully assembled including the hammered glass. Shown here upside down.

|

|

|

The first compartment door blind cover after machining. Photo: Brian Oldford. The lavatory ceiling panels is complete with more corner coving added. Photo: Rob Massey.

|

The end mouldings installed ready for the corridor connection. Photo: Rob Massey.

|

|

|

The moulding above corridor connection offered up. Photo: Rob Massey. The ceiling and corner moulding in the north end lavatory. Photo: Rob Massey.

|

Further end mouldings manufactured. Photo: Rob Massey. Tongue and groove panelling trimmed to size for the partition. Photo: Brian Oldford.

|

|

| March 2024 | ||

|

We've started making new mouldings for the coach end. Photo: Rob Massey. The north end lavatory ceiling framework nearing completion. For orientation, this is looking up from the floor to the ceiling. Photo: Rob Massey. The south end underframe following the welding repairs. Photos: Rob Massey. Compartment door now with latch fitted. Photo: Mick Haynes.

|

Trial fitting the lavatory window bolection. Photo: Rob Massey. Partition being routed to take tongue and groove paneling. Old and new toilet bolections. Photo: Mick Haynes. The lavatory base in position. Photo: Mick Haynes.

|

|

| February 2024 | ||

|

The south-end buffer and drawbar area being painted. Photo: Dave Smith.

|

The corridor partition in workshop for modification to toplight version. The lavatory partition now with joggle.

|

|

| January 2024 | ||

|

One of the study oak posts for the lavatory partition. Photo: Brian Oldford.

|

Tongue and groove for the Lavatory wall being fitted.

|

|

| December 2023 | ||

|

One of the corridor partition from our spares stock. We have 8 of these and we will take them apart and modify then to suit 2426. The width will be reduced to suit the 5' 10 1/2" compartment, the quarter lights lowered and horizontal rail repositioned. |

The polishing of all 80 blind brackets, plus 4 spares, has been completed! Photo: Dave Smith.

|

|

|

The oak lavatory door is now varnished. Front side. Photo: Rob Massey. And the rear side. Work continues on the other, Mahogany, door. Photo: Rob Massey. View of the south end with the floor, the end bar removed and the first section of the bottom-side on the compartment side. This has also exposed the top web of the headstock for repair. Photo: Rob Massey. The old end bar and end of bottom side. The newness has definitely gone off:) Photo: Rob Massey.

|

One of the nine new bolections for the corridor side windows. The first corridor side bolection installed. Some of the mouldings removed from the south-end which will act as templates for replacements. Door no. 16 has been removed. Its condition is reasonable.

|

|

| November 2023 | ||

|

Much work has gone on exposing the south-end framework removing bolts, screws and pins. The sides will also be prepared along to the first of the external doors as the bottom-side repairs will go up to the first doors on each side. Photo: Rob Massey. The first vestibule door has been assembled after completing the mortices. Dave and Mike working on the mahogany lavatory door vacant/engaged latch and its hinges.

|

Cleaning of the blind brackets has reached 48 out of the 80 to be done. Photos: Dave Smith. Further blind brackets polished.

|

|

| October 2023 | ||

|

Scissors gangway frames. John Ashton admiring the first set of scissors gangways. Photo: Dave Smith.

|

Lavatory door with panels and beading.

Blind brackets polished. Stiles and strike posts for vestibule doors.

|

|

| September 2023 | ||

|

There is continued progress with the gangway metalwork. Timber packers has been fitted to the north end and most of the drilling for the scissors brackets is complete. Photo: Dave Smith. |

||

| August 2023 | ||

|

The north end headstock is now fully painted. This end is also being prepared to fit the timber packing behind the corridor connection. This is in undercoat and will be fitted shortly. Photo: Dave Smith.

|

||

| July 2023 | ||

|

The compartment sliding doors progress. Photo: Mick Haynes.

|

||

| June 2023 | ||

|

Compartment sliding doors with top and bottom runners added. Photo: Mick Haynes. Blind brackets fitted. Photo: Mick Haynes. |

Internal droplights being varnished. Photo: Mick Haynes. Buffers in undercoat. Photo: Dave Smith. |

|

| May 2023 | ||

|

The compartment door fittings being cleaned and polished. |

Cleaning painting the underframe progressing, in red primer to the right and grey undercoat to the left. Photo: Dave Smith. The dynamo sling bracket offered up for drilling. Photo: Rob Massey.

|

|

| March 2023 Update | ||

|

We've almost completed the solebar cleaning apart from the sections behind the steps. Photo: Dave Smith. The repairs to the internal droplights are complete and the first coat of varnish applied.

|

We've successfully removed the second north-end buffer - finally!

|

|

| March 2023 | ||

|

Compartment doors assembled and backs fitted.

|

Gangway door. This is from a contemporary GWR diner, dia H15 Lot 1115 no. 9526. |

|

| February 2023 | ||

|

Five compartment sliding doors in various stages of assembly. Sliding door assembled.

|

Corridor side solebar progress. Two of the four spare lavatory doors in our possession are being stripped down and new interior panels are being cut.

|

|

| January 2023 | ||

|

A buffer guide removed from the south end to expose the strengthening plate which will be partially replaced. Work has also begun to strip the solebar on the corridor side.

|

Set of parts for compartment sliding doors. Mortices cut and cross pieces ready for trial assembly of the doors. Photos: Mick Haynes

|

|

| December 2022 | ||

|

Vestibule handles polishing up nicely. Photo: Dave Smith. |

||

| November 2022 | ||

|

The underframe cleaning has concentrated on the vacuum pipe. The photo shows the dynamo tensioning stay, the tie rod and the dynamo pulley. Also visible are the three holes in the underframe which will take the bolts of the dynamo bracket. On Toplights these had to be cranked to avoid the vacuum pipe. Photo: Dave Smith

|

The new section of reinforcing plate behind buffer shank fitted ready for welding. |

|

| September 2022 | ||

|

The first of the four Queen posts has been stripped back and painted. Thanks to help from Graham Phillips, the buffer has been removed and the area cleaned and primed ready for the new plate. The buffer has been cleaned and greased and the guide has also been de-rusted. |

|

Work is continuing with the construction of 8 toplight compartment sliding doors. Six and a half BE doors have been de-constructed so far. The set of parts now awaiting paint removal has grown and cleaning off has begun. Progress has also been made on manufacturing GWR “original style” blinds. Here's an original blind with a sample of the new material on the left side. We're very pleased with this and we will order a quantity of material to make new blinds.

|

| July 2022 | ||

|

More of the solebar has been cleaned off and the battery boxes and being bolted to the brackets.

|

The headstock is being cleaned back and primed. Some repairs will be necessary here. |

|

| June 2022 | ||

|

Both the new battery boxes are in position although are still to be bolted in.

|

We've started cleaning the solebar.

|

|

| April 2022 | ||

|

Work is continuing on Churchward Third 2426 with sections of the underframe cleaned and primed.

|

||

| February 2019 | ||

|

Metalwork has been prepared to construct a new scissors gangway.

|

||

| January 2019 | ||

|

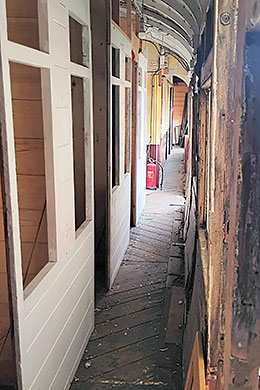

Part of the corridor side frame before work started. A new corner post in place. Internal paneling ready for reinstatement.

Photos: Mike Walker |

Frame repairs proceeding well. End repairs to the compartment-side northern corner. End frame repairs complete. New toilet flooring.

|

|

| September 2016 | ||

|

||

| |

|

|