|

||||||||||||||

Bridgnorth MPD and BoilershopA few occasional images and notes from around Bridgnorth works. |

||

September 2009 |

||

|

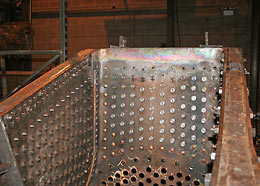

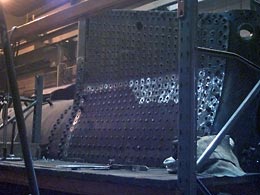

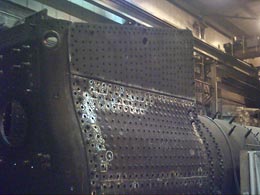

2857's frames lifted on the jacks and largely dismantled... ...initial work is concentrating on replacing loose rivets and fitted bolts - circled.

|

2857’s tender in the paintshop - livery will be Hawksworth style with large GWR on the tender. 7714 - now withdrawn from traffic, it will swap places with 1501 in the Engine House, Highley, while the spare Pannier tank boiler is overhauled.

|

|

| May 2009 | ||

|

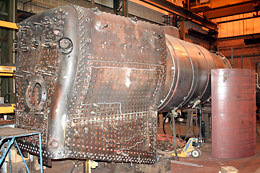

In the boilershop, a new smokebox door for 2857 - no number plate or shed plate! 2857's boiler with the fireman's side strengthening patch nearing completion. Similar patches for 80080's boiler. The right hand side (the boiler is upside down here) has been formed and patch screws fitted while the left hand patch has been welded to the wrapper in preparation for more the same. In the main shed 2857's tender is back on its wheels while attention focuses on re-assembling the brake gear... ...the frames are now on the jacks ready for lifting. |

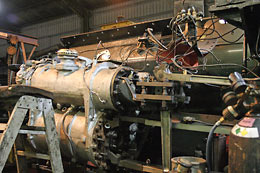

43106 edges nearer to completion with a move from the boilershop round to the shed for final assembly... ...lubrication pipework almost complete... ...along with footplate fittings... ..and we must be getting close! Out in the yard - an initial steam test is imminent! Photographed 30th May by Paul Bennett. |

|

| February 2009 | ||

|

2857's frames over the pit, the crossheads split and the pistons removed... ...while the tender is on the jacks, brake rigging dismantled, wheels out and re-profiled. At long last work has started to provide the doors on the main shed, along with other improvements to keep the water out! Work is moving along promptly on the steam crane boiler in preparation for a big lift at Highley!

|

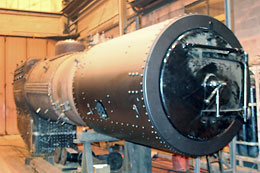

43106 has been shunted round to the boilershop in preparation for refitting the boiler... ..which is outside with a warming fire ready for the official steam test. The throat plate has been removed from the spare pannier boiler. On 80080's boiler most of the crown stays are in, set to length, caulked and a start made on fitting the protective nuts over the exposed threads.

Photographed 6th February by Paul Bennett.

|

|

| January 2009 | ||

|

The major overhaul of 43106 continues... ...the newly cast and machined front cylinder cover is fitted. 46443 has been up on the jacks for a speedy repair to the front pony truck. Behind is the tender from 2857, next on the jacks for dismantling and overhaul. |

In the boilershop, 43106's boiler is ready for a visit from the boiler inspector and an official hydraulic test... ...and recently arrived is the boiler from the 30T steam crane. Another joint volunteer/full time staff project. Photographed 16th January by Paul Bennett. |

|

| December 2008 | ||

|

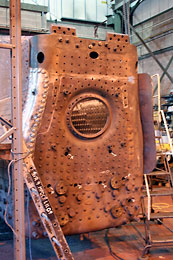

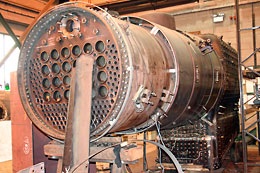

In the boilershop the spare Pannier Tank boiler has had temporary cross members welded in, these will maintain the outer firebox in place while the throat plate is removed. Close up view of grooving on the pannier tank backhead... ...with another close up view of shewing cracking between the stay holes. 2857's boiler turned on its side to allow work on the next phase, this will include completing riveting around the front tubeplate. 43106's boiler prepped for hydraulic test. |

In the (dark) shed, 2857 has moved up from Bewdley for the start of its mechanical overhaul. On 43106, a new pattern for the missing front cylinder cover has been made, cast and is currently being machined... ...the cab is on... ...and the injectors fitted and piped up.

Photographed 13th December by Paul Bennett. |

|

| November 2008 | ||

|

The spare GWR pannier boiler has come back into the boiler shop for some serious platework replacement. Most of the backhead will be replaced... ...grooving around the foundation ring can clearly be seen on the waterside of the removed backhead. 43106's smokebox is complete and riveted to the barrel. The boiler is largely blanked off in preparation for the hydraulic test. Earlier in the year with Catch Me Who Can on display at the Autumn Gala. |

Work on 80080's boiler continues... ...on the new section of backhead... ...and throatplate. New sections of the outer wrapper have been let in too. Repairs to the flanges on the copper tubeplate are complete and small tube hole enlarged and bushed back to tube size.

Photographed 29th November by Paul Bennett.

|

|

|

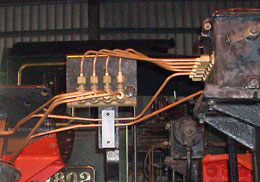

Charles Lamont has produced some very neat lubricator pipework on 43106.

|

We doubt Darlington built it originally with pipework so neat, as this image shows - some which definitely is not Charles' work. This will be revamped more in accordance with his standards. |

|

| August 2008 | ||

|

The Bluebell's Dukedog 9017 at Bridgnorth works for a V&P overhaul. |

GWR Dukedog 9017 from the Bluebell has arrived at Bridgnorth for a valve and piston examination/overhaul. The EMF engineers have been assisting the full time staff with this fascinating loco. Terry Jenkins writes: "The overhaul work on 9017 has involved a valve rebore plus new rings and new piston rings. A certain amount of dismantling and reassembly goes with the job to make it possible to fit the boring bar into position to rebore the valve sleeves. The work is well underway with the valves being completed and piston rings due to be fitted this week. The buffer beams are getting a repaint and the correct style of front number is shortly to be applied. On transfer light engine to Bridgnorth it was interesting to note just how smooth riding this loco is. As far as we can tell it is directly descended from 'Bulldog' 3425 (unnamed) of 1906 and 'Duke' 3258 'The Lizard' of 1895. There are however other stamped numbers in various parts - one of the cab windows coming from Bulldog 'Tre Pol and Pen'. This loco and 'The Lizard' were long time Machynlleth shed residents along with our own 7802. The loco still has a number of old GW features now rarely seen such as the lubricator for the regulator valve on top of the dome and a single glass hydrostatic lubricator. Perhaps we could keep it and get it fit to run on the Cambrian again (with 7802/12 & 7325) - oh for a lottery win!!!!!" As well as this year's SVR Gala the loco will be appearing on an EMF photo charter and GW(SVR)A's 40th Anniversary train.

|

|

|

In the boilershop 80080's boiler has had a visit from the code welded to weld in the new section of backhead and... ...throatplate. 43106's boiler, with firehole riveted leaving very few jobs on the boiler assembly. Catch Me Who Can is back from a visit to Barrow Hill. The crosshead and connecting rods are almost ready for fitting. |

A poignant moment as 45110's tender is emptied following its last steaming (for now). The frames of 43106 have been re-wheeled! The driver's side motion has been reassembled - valves and pistons next. The 8F is ready for the move to the Engine House via Kidderminster for turning. A good day's team work from the Boilershop Foreman and 2857 volunteers saw 67 foundation ring rivets in 2857's boiler.

Photographed 30th August by Paul Bennett. |

|

| July 2008-2 | ||

|

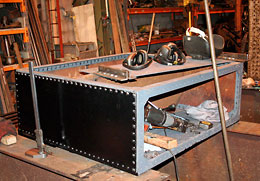

Despite of much burning of the midnight oil there's still quite a few of the component parts for Catch Me Who Can to complete such as this crosshead... ...and the watertank. 43106's tender fresh from the paintshop... ...but the frames are still on the jacks. In the boilershop all 43106's tubes and superheater flues have been expanded in place... ...the cladding removed for painting... ...and the new smoke box has been marked up for drilling and cutting of the various apertures. Transferring dimensions from the old one has revealed not to drawing, slightly off centre holes for the saddle - this is being replicated for future historians to puzzle over! |

80080's backhead is prepared for welding in a new section... ...which is being made on the bench. The copper tube plate has been remove from 80080 and here a new flange welded in. The largely volunteer overhaul of 2857's boiler is continuing well with the new front tubeplate now in place and all holes reamed ready for riveting up. The paint work being rubbed down on 8F 48773 for repaint prior to display in the Engine House. The King was still in residence while problems with the air brakes were resolved.

Photographed 12th July: Paul Bennett. |

|

| July 2008 -1 | ||

|

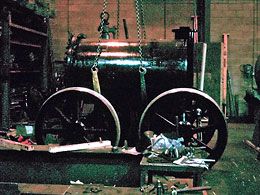

Having passed its insurance exams Catch Me How Can is readied for this weekend's Trevithick 200 event, 19-20th July Severn Park, Bridgnorth. Photographed 12th July: Paul Bennett. |

|

|

| June 2008 | ||

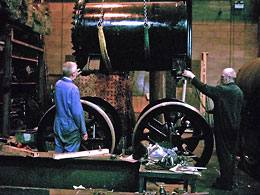

A significant stage in the construction of Catch Me Who Can, as the boiler is set down on the wheels. 19th June. Captured on Brian Oldford's steam driven camera!! |

||

| May 2008 | ||

|

Catch Me Who Can; the axle bearing points are welded on the boiler barrel and… …the wheels pressed onto the axles and flanges machined. Project Engineer, Dave Reynolds, has made the wheels with an integral tyre to remove any likelihood of it moving on the wheel centre as it's so powerful!! Further info as the big day approaches from the Trevithick 200 website. 80080; with foundation ring back in place and the wrapper sections temporally welded back in (these had been cut out prior to the SVR taking on the job). This will give the necessary reference points for the new sections of throat plate and backhead. Photographed 17th May: Paul Bennett.

|

43106, tender tank and frames re-united and now in the paintshop. The reverser on 43106 is back in place. 43106; a complete new set of cladding has been fabricated and trial fitted around the crinoline supports, while… …the small tubes are installed and the bottom rows expanded in place. |

|

March 2008 |

||

|

41306's tender tank has been brought in to the boilershop in preparation for lifting... 46443 over the pit having been brought up from Bewdley for a V&P exam. The wheels for the 'Catch Me Who Can' replica have been machined from flame-cut blanks - no flanges! |

...on to its frames. Work continues drilling out the tough monel metal stays from the firebox of 80080.

Photographed 15th March: Paul Bennett.

|

|

| February 2008 | ||

|

43106's boiler turned upright again, hopefully for the last time now the foundation ring riveting is complete. On 2857's boiler the foundation ring is back in position with many holes reamed out in preparation for riveting. Ye Olde Worlde safety valve mechanism... |

43106 with new snifter valve, made from Bridgnorth pattern shop patterns, fitted on top of the steam chest. ...on the intriguing 'Catch Me Who Can' replica.

Photographed 23th February, Paul Bennett. |

|

| January 2008 | ||

|

In the Boilershop contract work on 80080 is progressing well with all the monel metal stays drilled out... The newly built boiler for the replica of Trevithic's 'Catch Me Who Can' (see Summer 2007 SVR News) has arrived from... 43106's boiler has been turned on its back and the foundation ring riveted in. The pairs of extended threaded horizontal rivets will support the rocking grate... 813 (as 816) is back at Bridgnorth for running maintenance before, hopefully, stretching its legs to HL. |

...from both sides of the throat plate. ...Israel Newton.

...while the vertical studs secure the hopper ashpan. Axle alignment jig set up on 43106.

Photographed 19th January, Paul Bennett |

|

| November 2007-2 | ||

A riveting time! Traditional boilersmith skills are still alive and well in Bridgnorth boilershop. This sequence of shots shows the 'can't be done' technique of riveting the copper firebox seams in situ, in this case on the copper door plate of GWR 2-8-0 2857. |

||

|

...and then passes the red hot rivet to Paul who picks it up with the long tongs... ...where Graham takes hold and pulls it through while Paul positions the block behind the rivet and has the long wedge ready... ...to form the rivet over... The finished result - after the rivets have been caulk and the seams dressed. |

|

| November 2007-1 | ||

|

43106's boiler has been turned on its other side to allow the opposite copper doorplate seams to be riveted... ....and the same on the copper tube plate. With the riveting complete the final row of stays adjacent to the tube plate can go in before the boiler is turned on its back in preparation for the foundation ring to be re-instated. 1501 looking a little smarter now following a visit from the Bewdley MPD cleaners. 4566 has moved up from Kidderminster (by road!) for running repairs and weighing to correct the weight distribution. |

The boiler from PRCLT's Standard 4 Tank, 80080, has arrived for a full contract overhaul. Plate work around the foundation ring had been cut away prior to its arrival. The firebox wrapper plates will be cut back further to the horizontal white line, a new section let in and all the stay replaced in this area.

Photos: Paul Bennett, 17th November 2007

|

|

| October 2007 | ||

|

Behind the Boilershop the water tank from Highley Station is in for repairs. A 2-8-0 set of wheels has arrived for re-profiling...

Photographed 13th October, Paul Bennett

|

...coupling rod re-metalled and machined... ...5164 receives some attention... ...while 1501 doesn't! |

|

| September 2007 | ||

Bridgnorth Station held its own mini Gala this year... ...the Jinty spruced up ready for the Engine House... ...while 5164 waits patiently...

|

...the 30ton steam crane gives a lifting demonstration... ...and a sea of new fitted bolts on Taw Valley's frames. |

|

| August 2007 | ||

|

Behind the boilershop is the recently constructed tender tank for 43106... ...to allow the copper doorplate... ...the outer firebox wrapper and throat plate riveted together and chalked. ...and wrapper plates holes reamed to final size and countersunk ready for riveting. ...view along the right hand side of the frames, superheater elements for 7812 in the foreground... Left hand side motion bracket with motion partly reassembled.. ...and finally Stanier Mogul 42968 undergoes a V&P examination plus a spot of motion re-metalling.

|

...while inside the boilershop 43106's boiler has been turned on its side... ... and firebox tubeplate seams to be riveted up... On 2857, the throat plate patches are complete... 43106; horn guide in place with new fitted bolts. A new pattern made in Bridgnorth volunteer pattern shop will be used to cast a replacement for the one broken. ...43106, lefthand cylinder with a nest of lubricating pipes... .... a few worn pins and bolts from 43106...

|

|

| July 2007 | ||

|

43106 now on the lifting jacks where the wheels were run out... ...and reprofiled and painted ready to be re-fitted. Photos: Paul Bennett

|

Meanwhile in the boilershop the inner firebox door plate has been reinstalled and most of the new stays fitted... ...along with most along the firebox sides as well. |

|

| May 2007 | ||

|

|

Now with number on the bufferbeam and GWR roundel on the tender, and a more few extra touches before traveling to Swindon. | |

| April 2007 - 2 | ||

|

A surprisingly smart looking 7819 Hinton Manor with repaint nearly complete prior to swapping places with 4930 Hagley Hall at Swindon. |

Western Courier in Bridgnorth shed after a lift up to the rafters on these powerful 25 tonne jacks to replace the fuel tank straps.

|

|

| April 2007 - 1 | ||

|

7819 Hinton Manor at Bridgnorth shed for cosmetic restoration and repaint before going on display. 813 in for some maintenance work before setting off on its travels again. Front ring of 43106's boiler barrel. This entire section, including the front tube plate, is new work. Mark Bradshaw heating platework inside the barrel of 43106 prior to some gentle work with the large hammer! 43106 looking though the firebox, with rear copper plate removed, to the new backhead - again completely new work.

|

47383 in the paintshop looking shinny, ready for display in the 'Engine Shed'. Taw Valley's frames.. ...and the re-tyred driving wheels ready for fitting. Meanwhile outside, clearance work in the grounds of... ...the cottage.

|

|

| March 2007 | ||

A quick check in the boilershop to see the second throatplate patch for 2857 being 'gently' formed. Not the sort of work for mid-summer! Further details on 2857's ongoing boiler overhaul can be found on the 2857 Society Web Site.

|

||

| December 2006 | ||

|

Volunteer Tony Pirie machines some pins for the transverse hornstays for 43106 from EN8 steel. Just some of the numerous parts being replaced or refurbished on the sickly chassis of this loco. The boiler's condition started no healthier but is slowing recuperating. A couple of shots of the replacement GW pannier smokebox tubeplate made In this photograph a 2857 team member is opening up the holes in the lower portion of the steel throatplate such that they will all be the same size. This is being done prior to the holes being bushed down to original size. This will permit the smallest sized stays to be used thus getting maximum life out of the brand new copper tubeplate presently under construction. |

On Saturday 9th December SVR Boliersmith Graham Beddow removed the lower portion of the firebox wrapper on the fireman's side of 43106's boiler.

Photos: Brian Oldford

|

|

| July 2006 | ||

|

Driver Townley gets some uncommon mileage delivering the P-Way DVT back to the cattle dock at Bridgnorth having had its accommodation bogies replace with its own refurbished ones at Kidderminster carriage works. Photo: Brian Oldford. |

Valve liners waiting for 43106. |

|

| April 2006 | ||

|

7714 on the lifting jacks with center driving wheels removed... ...for a £20,000 rebuild of the crank axle. This work is being supported by this Summer's SVRA raffle. |

813 on shed for repairs to it's brake gear after a mishap on the lowloader. Now fully repaired and visiting the Cholsey & Wallingford Railway for the Summer. |

|

| |

| © 2006 GW(SVR) Association. Page created June 2006, last updated: 23 October, 2009 Webmaster |